Many applications have components that must be absolutely leakproof to ensure proper operation. Leak tests are commonly carried out with pressure transducers that have to meet high requirements.

Applications and components that have to be leakproof are, amongst others:

- Engines, brake systems, air conditioning systems, cylinder heads, valves, filters, fuel and injection systems

- Packaging in the food industry or medical technology

- Electric appliances

- Refrigeration systems

- Hydraulic systems

Components that have to be tight are usually sealed before installation. The equipment used for leak testing must therefore work very reliably during production.

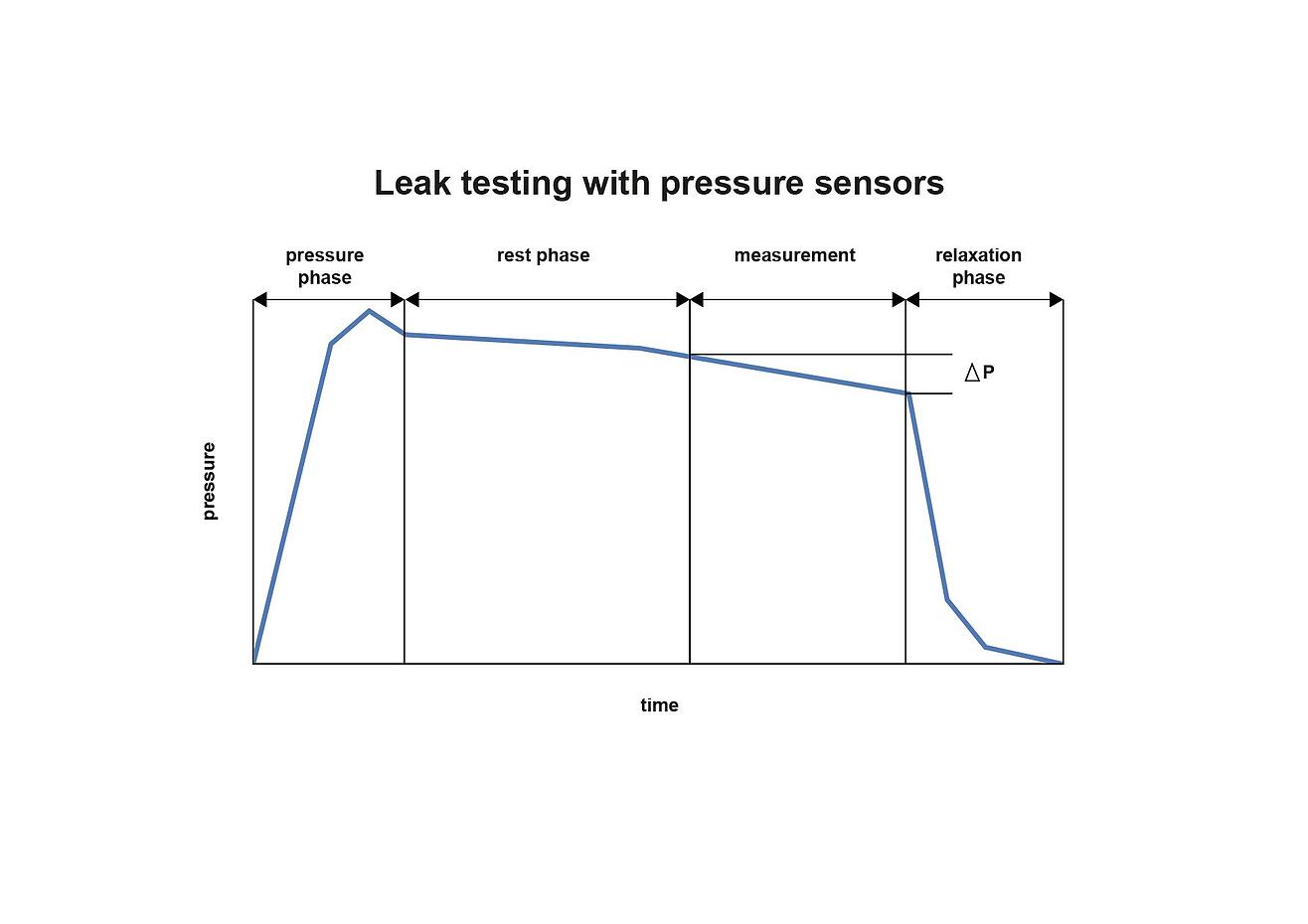

Usually, leak testing is carried out by means of a pressure measurement. Pressure is applied to the component. The pressure is measured again after a rest period. If a pressure drop has occurred between both measurements, the component can be considered leaking.

The stable and precise function of the pressure sensor used for the test is crucial for the detection of leaks. In particular, the requirements regarding stability and the adverse effects of atmospheric noise are very high. Even minimal pressure losses must be detected reliably.

For example, accuracy values should not exceed 10 … 20 Pa or 0.001% … 0.002% of the full scale for a 10 bar sensor.

STS has been manufacturing leak detection sensors for years, including the ATM series analog pressure transmitters with a 4 … 20 mA output signal. The high-precision measuring element detects even low pressure losses in the mbar range and thus meets the high requirements of leak testing applications.

The mechanical design (process connection and electrical connection) does not affect the behavior of the sensor and can be configured thanks to the modular design principle employed by STS.

The pressure sensors of the ATM series are available with different output signals. In this application, however, it is important to use 4 … 20 mA as this robust output signal is largely unaffected by atmospheric noise.

Read more about leak testing here.