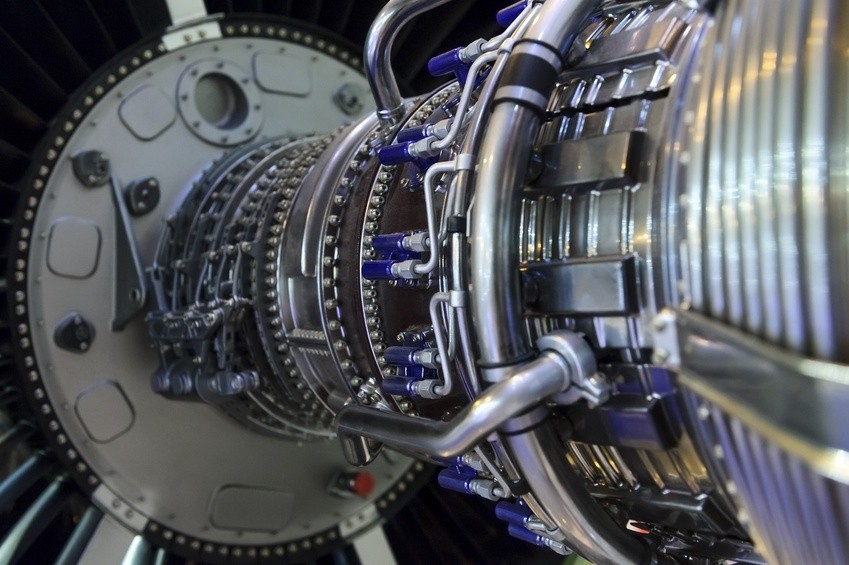

Test fixture pressure sensors – Pressure measurement in the aircraft engine compartment

As many engineers have found to their chagrin, dealing with pressure measurements in the engine compartment of an aircraft can be a delicate and frustrating experience. The heat, vibrations, orientation, and a multitude of other factors come into play. So how can we hope to develop a method for consistent and accurate readings? Well naturally, we’re left with hours, days, and most likely months of testing! However, we still need a test sensor that can rise to the occasion, function through all these changing conditions, and continually produce correct and repeatable results. We are engineers after all, and repeatable results are an occupational necessity. Thankfully for us, STS has stepped up to the plate to provide a complete series of pressure sensors to meet all of our testing needs. Where those needs can range from specific temperature requirements, size constraints, sealing material, and electrical output signals. All of these requirements will be covered in the following article as we address STS pressure transmitter usage for our testing needs.

Continuing with our engine compartment example, let’s zero in on the oil pressure. One of the first concerns while selecting a pressure sensor for this test is temperature resistance. Naturally, it gets quite warm next to an aircraft engine; therefore, we must ask ourselves, can the sensor be mounted alone or does it need a heat shield? More importantly, will the sensor even function properly when the components begin to heat up? Erratic oil pressure readings are very low on the wish list for a pilot! Therefore, both are valid points; but don’t fret too much. The STS line of pressure sensors include excellent temperature resistance, up to 125° C. This, in most cases, takes care of our initial temperature concerns and allows the sensor to be mounted it the most logical position in the engine compartment without the need to worry about temperature interference. Furthermore, we can fiddle, finagle, and fine-tune the test sensor’s location without constantly looking over our shoulder to see if the increased temperature will manipulate our results. This provides us with a great deal of flexibility when constructing our test plan.

Along the same subject of mounting locations, the size of the sensor is also crucial. Trying to wedge an ungainly box next to your sleek engine for a series of oil pressure tests would undoubtedly result in a few raised eyebrows amongst all those concerned. Additionally, space in this area is constantly at a premium. However, that is one bridge you don’t have to cross as STS has produced a very compact and low profile pressure sensor that makes for convenient mounting throughout your testing area of operations. Thanks to the advanced customization options, which we’ll discuss later, the exact dimensions vary from sensor to sensor. However, they tend to fall within the 50-60mm (2.0-2.4”) range. This small size allows for easy fixturing using common Adel clamps or any other off the shelf bracket without spending the time to design a custom mounting scheme, or trying to dream up a new overly complicated fixturing method every time the sensor has to be relocated to find the optimal position for oil pressure readings. All in all, this is certainly a time saver when we are focused on a timely and efficient series of tests.

The last factor that we’ll touch on that can be invaluable for our pressure testing is customization. More often than not, the pressure sensors that are readily available on the market for such a test have a well-defined scope that they operate in. A single configuration that works best in ‘this’ pressure range, for ‘that’ frequency of collection, and it all comes with just ‘this’ product design. However, STS pressure sensors offer several options and customizations that give us the freedom to not limit our test based on our sensor’s individual capabilities.

For our example, we of course must have a sealing material that with neither contaminate the oils, nor degrades with constant exposure. Well, we have several options for the sensor seals that can accomplish just that, including EPDM and Viton to ensure that the sensor is operating at peak performance for the entire test. Or, conversely, we can opt for a metallic sealing option to ensure proper test results. What’s more, perhaps we need a frontal diaphragm connection, with a PUR cable, along with 20 mA output signal. STS can deliver exactly that, along with any number of other combinations to ensure that the process connection, electrical and output signals, pressure connection, and seals are exactly what we need. In essence the sensor is cherry picked for our test and not simply some component we need to shoehorn into the test setup.

To recap, we are required to design a series of oil pressure tests; and as with most tests, many of the factors will be manipulated. The heat, mounting method, pressure range and a mind-numbingly large number of other issues will all be changing constantly over the course of the test. To cap it all off, we need a test pressure transmitter that can fit into this envelope and consistently produce accurate results. Well we can at least nip that problem in the bud straight away by incorporating an STS pressure transmitter for our testing regimen. The high temperature and pressure ranges, combined with custom seals, process connections, electrical and signal outputs, and overall design ensure that this is a sensor that can pre-configured to slide seamlessly into your testing apparatus, and not require that your entire system by reconfigured to suit the sensor.