Minimizing pollutant emissions using pressure-sensing technology

Recall actions in the automobile industry have widespread consequences. Manufacturers have to contend with a huge image loss, as well as higher costs. Vehicle owners, on the other hand, react with anger and uncertainty. A particularly major stir has welled up over the past year with the scandal surrounding manipulated emissions figures. Politics has in turn reacted and signaled towards new testing procedures.

The automobile industry has triggered a true recall-crisis over the last two years. In the USA alone, some 51 million vehicles were ordered for recall during 2015 by the National Highway Traffic Safety Administration (NHTSA). This far exceeds the number actually sold in that same year, even though the vehicles recalled were not all connected to manipulated emissions figures. Some 11 million of these vehicles originate alone from the “Dieselgate” scandal involving the manufacturer Volkswagen. The losses involved are enormous.

Cost pressure and an increasing complexity of the systems built into vehicles are associated with heightened error susceptibilities and their resultant recall actions. This challenge is to be met primarily through improved and even more reliable control systems – on the part of manufacturers and suppliers, as well as government supervisory bodies responsible for legal specifications monitoring. High-grade measurement equipment is therefore needed, which can deliver the most precise of results under varying conditions and thus secure an optimal standards qualification (or post-qualification). A major backlog demand has since opened up in this respect.

The best pressure measurement technology for the best combustion engines

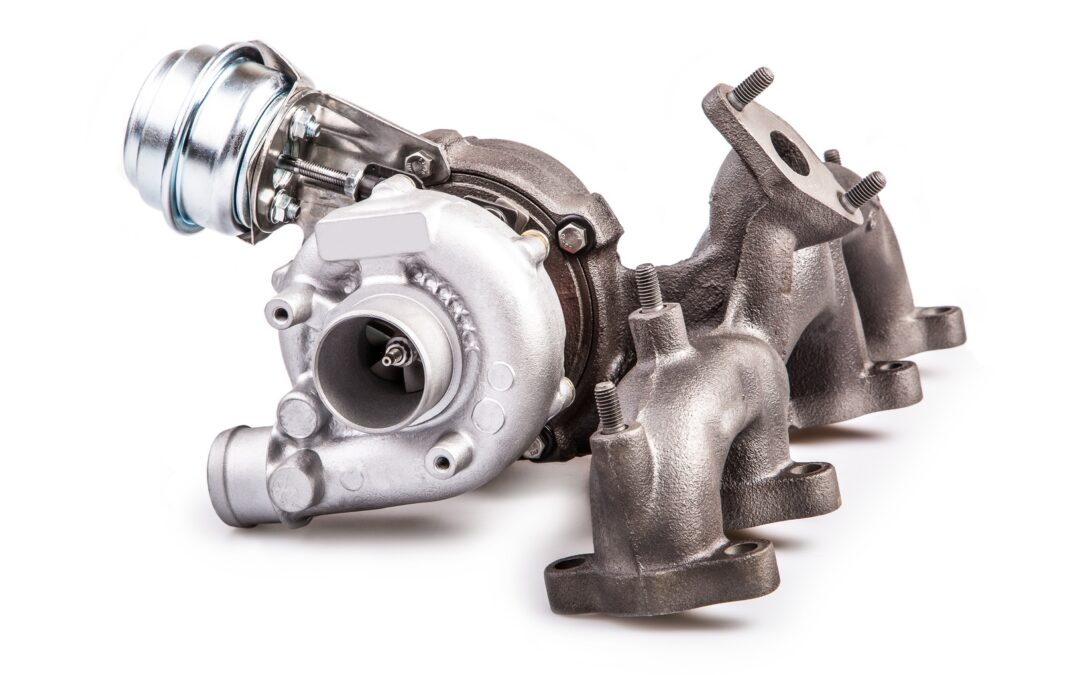

In the development of combustion engines, high-precision pressure transmitters are required, which, during combustion analysis, can facilitate the exact measurement of cylinder pressures, as well as intake and exhaust pressures. Absolute pressure sensors (gas exchange) and high-pressure sensors (injection pressure measurement) must also be of the highest-grade, since, in the latter instance especially, the potential for pollutant minimization is enormous. In this regard, particulates from gasoline engines can be reduced through an increase in injection pressure. Some suppliers are already working on increasing injection pressures to 350 bar or even higher.

Mobile emissions measurement is on the way

The standardized “New European Driving Cycle (NEDC)” is currently being introduced for exhaust and consumption measurements by state regulatory agencies. As we have witnessed, test procedures have given manufacturers all the freedom to influence measurements to their own advantage, since the vehicle is examined only in a test facility rather than under real-world conditions.

Once the manipulations became known, the Committee of Experts from the European Union decided in May 2015 that emissions during type approval are to be tested from late 2017 under practical driving conditions – known as Real Driving Emissions (RDE). The laboratory conditions for conventional checks will be supplemented by a procedure that prevents the use of cut-off devices during testing. The vehicle to be tested will be examined on an open track and thus subjected to variable conditions. Furthermore, random braking and accelerating procedures will also be performed.

Meeting new challenges – using modular pressure-sensor solutions

The RDE procedure obviously poses particular challenges to the measurement technology deployed. In the optimization of emissions figures for combustion engines, initial emphasis falls upon absolute and relative pressure measurement. With the new measurement procedures in mind, these need to perform reliably across a broad temperature range. Whether in the depths of winter or the heights of summer, measured values must be absolutely reliable to reflect a realistic picture of the true exhaust figures. It is also evident that operation at higher pressures can achieve significant reductions. For this reason, higher pressures must also be measurable. The fact that the pressure sensing technology employed operates without failure in mobile applications, given the new procedures, goes largely without saying.

Standard solutions cannot achieve this objective. Even more than that, they are actually part of the problem. Individual challenges require individual solutions. Also required are instruments that are precise as well as flexible enough to perform reliably in differing applications. Only by following this path can cost-efficiency and precisions be reconciled. It is clear that modular systems would be ideal in this context. In coordination with the manufacturer, these can be adapted to individual requirements and thus deliver highly reliable results. This represents a particular advantage in the development of new engines, since the adaptations can be made both straightforwardly and also promptly.

An experience that our customers have been making daily – and for almost 30 years now. As a leading manufacturer of customer-specific, modular measurement systems, we can provide tailored pressure measuring solutions within a short timeframe and in a proficient cooperation with manufacturers. Viewed from a measurements perspective, there exist no obstacles to the development of new, fuel-efficient engines, as well as to their testing under real-world practical conditions.