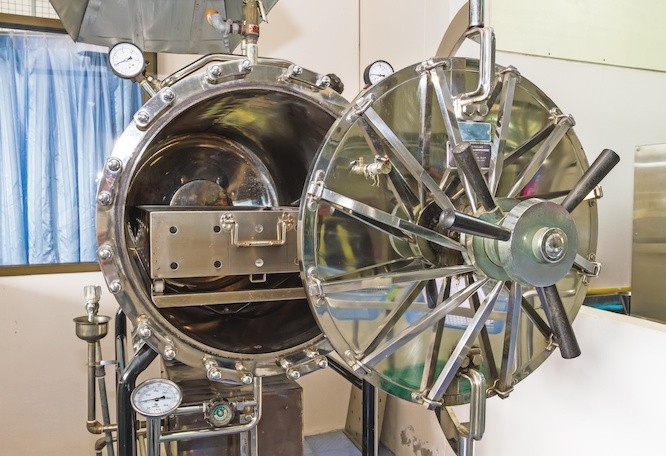

In some applications, pressure transmitters have to work reliably when exposed to very high temperatures. Autoclaves used to sterilize equipment and supplies in the chemical and food industries are certainly one of these demanding applications.

An autoclave is a pressure chamber used in a wide range of industries for a variety of applications. They are characterized by high temperatures and pressure different from ambient air pressure. Medical autoclaves, for example, are used to sterilize equipment by destroying bacteria, viruses and fungi at 134 °C. Air trapped in the pressure chamber is removed and replaced by hot steam. The most common method for achieving this is called downward displacement: steam enters the chamber and fills the upper areas by pushing the cooler air to the bottom. There, it is evacuated through a drain that is equipped with a temperature sensor. This process stops once all air has been evacuated and the temperature inside the autoclave is 134 °C.

Very accurate measuring at high temperatures

Pressure transmitters are used in autoclaves for monitoring and validation. Since standard pressure sensors are usually calibrated at room temperature, they cannot deliver the best accuracy under the hot and wet conditions encountered in autoclaves. However, STS has recently been approached by a client in the pharmaceutical industry that requires a total error of 0,1 percent at 134 °C measuring -1 to 5 bar.

Piezoresistive pressure sensors are rather sensitive to temperature. However, temperature errors can be compensated so that the devices can be optimized for the temperatures encountered in individual applications. For example, if you use a standard pressure transmitter that achieves 0,1 percent accuracy at room temperature, the device would not be able to deliver the same degree of accuracy when used in an autoclave with temperatures of up to 134 °C.

Users who know that they require a pressure sensor that achieves a high degree of accuracy at high temperatures hence need a device that is calibrated accordingly. Calibrating a pressure sensor for certain temperature ranges is one thing. However, the client who inquired about the autoclave application with very high accuracy demands had another challenge for us that was even trickier to realize than a properly calibrated sensor: not only the sensor element was to be in the autoclave at 134 °C, but the complete transmitter including all electronics had to go in there, too. Unfortunately, we cannot go into specifics as to how we were able to assemble a digital transmitter that both delivers the desired accuracy of less than 0,1 percent total error at 134 °C but whose other components can handle the hot and moist conditions as well.

In short: Piezoresistive pressure sensors are sensitive to temperature changes. However, with the right know-how, they can be optimized for the requirements of individual applications. Moreover, not only the sensor element can be calibrated accordingly, the whole transmitter can be assembled in a way that even hot and wet conditions can be managed.