The right sealing solution for every application

In order to maintain the performance of piezoresistive pressure sensors and optimally protect them in harsh conditions, various sealing options should be taken into consideration. STS offers several solutions here, which are selected according to the given requirements and the actual application environments.

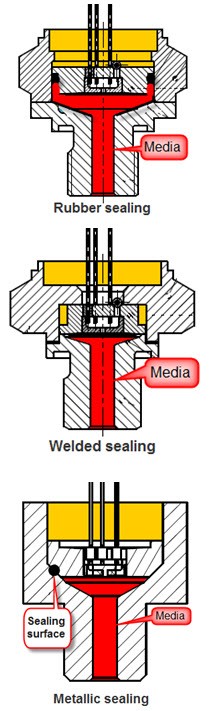

A sealing ring, or O-ring, is used in most standard applications. This common sealing method is very flexible and highly versatile. STS offers sealing rings in many different product variants, where the specific material is selected according to the pressurized medium.

Should the seal be exposed to aggressive media or extreme temperature conditions, sealing with a simple ring then becomes insufficient. The elastomers commonly used in the manufacture of O-rings become porous when exposed, for example, to media containing hydrocarbons. Problems can also arise during decompression, where a steep pressure drop may even rupture the sealing ring.

A common alternative to the simple sealing ring is a welded seal, where the measuring cell and pressure connection are welded directly together. This type of seal is somewhat more stable, but, just like the O-ring, can only withstand a maximum pressure of 250 bar/3600 psi. Up to this value, the O-ring and welded seal would complement one another, depending on the application environment and the predominant medium. With an aggressive pressure medium like gasoline, for example, only the welded seal would be suitable, whereas in saltwater, an O-ring should be strictly used to prevent corrosion of the seal.

Overview of the various sealing solutions

As soon as the limit value of 250 bar is exceeded, only a metal seal can then be used. At STS, this elastomer-free metal seal is therefore offered for application environments at very high pressures. Because of its properties, this sealing solution can also withstand exceptional conditions and extreme exposure to corrosive chemicals, vacuums and intense radiation exposure.

Practical use of sealing solutions

A large company that manufactures grinding and compressor systems for various industries relies mainly on the pressure sensors offered by STS, for which there is a wide range of sealing rings. Here the temperature conditions, as well as the nature and compatibility of the media, are known in advance, so that these can be easily validated before use and the sealing rings manufactured accordingly.

For another customer who manufactures test beds for the automotive industry, the material involved and the temperature conditions encountered are only lastly determined by the end user. The essential properties of the sealing solution therefore depend upon these subsequent specifications. The seals used here must therefore ensure from the outset a high degree of flexibility, meaning that our robust welded seals form the choice here.