The pressure connection (also process connection) is the element via which the process medium is directed towards the pressure sensor. As with the seals, there are different variants here. As always, the requirements of the respective application determine the choice of the appropriate components.

There are a variety of pressure connections to meet the needs of different industries, as well as meet the national standards of different countries. The basic distinction, however, is between pressure connections with internal and front-flush membranes.

Pressure connections

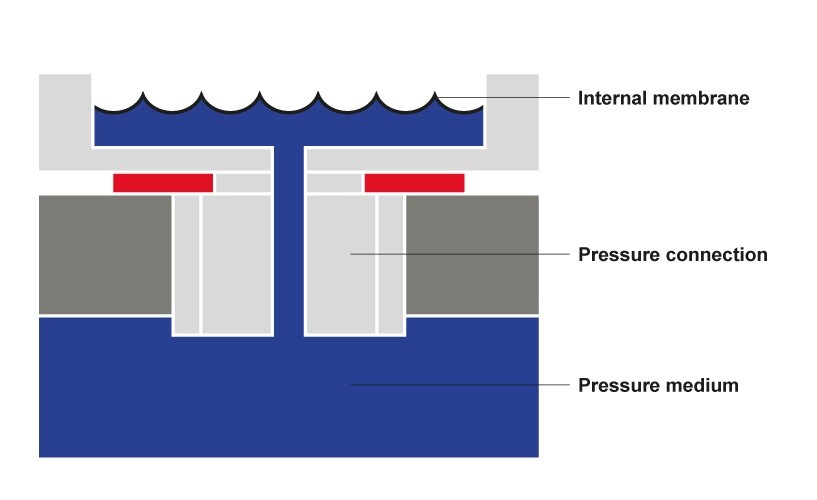

For pressure connections with an internal membrane (Figure 1), the pressure medium reaches the sensor membrane via a channel. This type of pressure connection is usually more cost-effective and is often used in applications with liquids and gases. In the case of the more solid process media, there is a risk of fouling the channel, which can ultimately lead to an influence on the measured results. Pressure connections with an internal membrane are also unsuitable for use in sterile applications.

Figure 1: Pressure connection with internal membrane

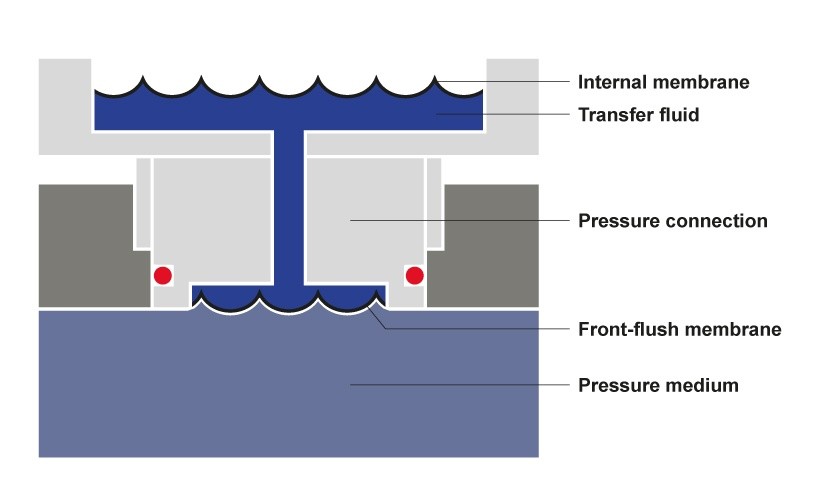

For front-flush pressure connections (Figure 2), the pressure channel is sealed from the front by a stainless steel membrane. The pressure is thus transferred indirectly to the sensitive sensor chip via a transfer fluid. This type of pressure connection is used when a residue-free cleaning is indicated (for example the CIP process). Also with viscous, solid and abrasive media, front-flush pressure connections are to be preferred.

Figure 2: Pressure connection with front-flush membrane

Screw threads and seals

The pressure connections usually have a thread with which they can be attached to the measuring point. Depending on the region, these threads may vary in form, with cylindrical pipe threads (G) being the most common in Western Europe.

The available seals, which are used between the housing and the thread, are just as varied as the thread types themselves. Here also, sector-specific and regional solutions have to be considered. In essence, it is generally the case that the materials are selected according to the existing pressure medium. In sterile applications (eg food industry), for example, O-rings made from Viton are used, since this is a fluoroelastomer exhibiting high thermal and chemical resistance. As a result, this material can also withstand the CIP and SIP processes.

Where appropriate, an application may also require the use of no sealing rings at all. Some types of threads are thus leakproof without the use of sealing rings at all. These tapered, purely metallic sealing connections achieve their sealing effect when the conical sealing surfaces of the components are wedged shut by a tightening of the threaded nut.

In the case of abrasive media or extreme cold or heat, the omission of O-rings for sealing is important. If, for example, a fuel such as diesel or gasoline is the pressure medium, then the measuring cell and the pressure connection must be welded together. The elastomers used for sealing rings would become rapidly porous under the influence of an abrasive medium. Direct welding, however, is not advisable in all situations. Here also, the medium decides upon the type of seal, since welding seams can corrode in brackish and salt water. A connection with O-rings will be required here.

Thanks to the modular construction of the pressure transmitters from STS, the pressure connections and sealing concepts can be flexibly designed and adapted to meet almost every requirement.