As the name suggests, the term diesel effect refers to the combustion process in a diesel engine. But it can also be observed in hydraulic systems. In addition to pressure peaks, oil aging, residues and the destruction of seals are the outcomes.

The diesel effect occurs as a consequence of cavitations. We will therefore first consider the formation conditions for cavitations in hydraulic systems before turning to the diesel effect itself.

Cavitation in hydraulic systems

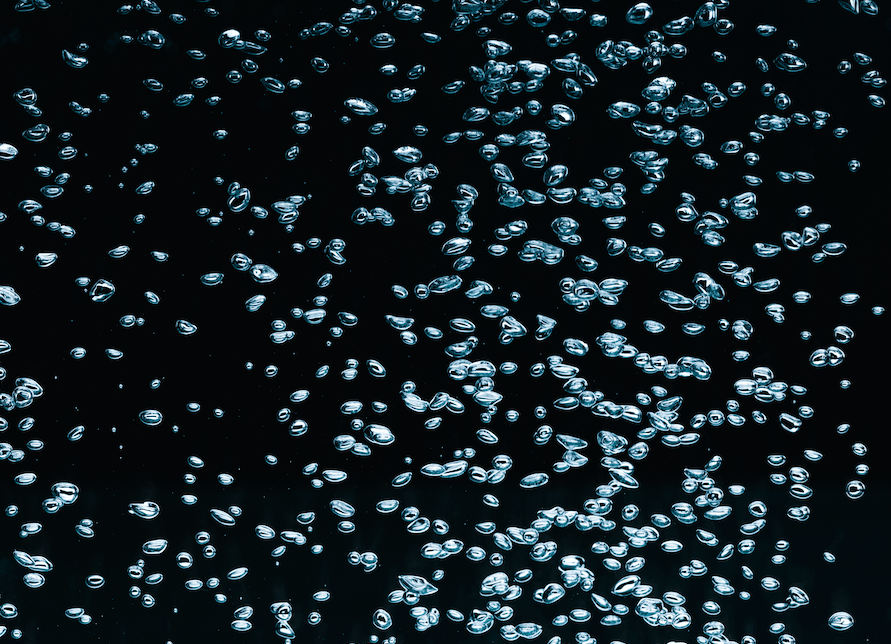

Depending upon gas, temperature, liquid and pressure, hydraulic oils contain dissolved air. Cavitation is ultimately an air expulsion from the hydraulic oil. This occurs when the oil is subjected to a certain pressure or shearing motion. In practice, this occurs in suction lines, pump interior spaces, cross-sectional narrowings and, in hydraulic systems, where pulsations appear. When the moving oil mass shears, voids are formed, into which the finest of air bubbles are released.

The diesel effect

If the air bubbles resulting from cavitation, which also contain oil particles, are subjected to a high pressure, then a drastic temperature increase occurs in those bubbles. This major temperature rise leads to the diesel effect, namely combustions within the hydraulic system, and this combustion process takes place within milliseconds.

The consequences of cavitation and the diesel effect

Cavitation can have a variety of negative consequences, including material damage to pump housings and pressure relief valves, the sucking away of sealing elements such as O-rings, altered flow characteristics, reduced function of pumps and gears due to filling losses, noise, pressure surges with pressure peaks exceeding the system pressure, and the diesel effect, in the form of oil aging, combustion residues and destroyed seals.

The consequences of cavitation and the diesel effect are not always immediately apparent. They are often only noticed when it is already too late and there is a need to repair the hydraulic system. Pressure peaks as a result of cavitation and the diesel effect can also damage the pressure transmitters installed in the system by overshooting. The sudden pressure increase in the system causes the membrane of the pressure transmitter to be “shot through” (read more about this here).

In view of the serious consequences of cavitation and the diesel effect, appropriate measures must be taken to avoid these phenomena. This includes a sufficient filling in the suction chambers and low flow velocities, as well as avoiding sharp edges, deflections and pulsating pressures.