STS Pressure Measurement – Customized Solutions

Working in partnership with you we develop a concept for the project to satisfy the specific measurement task. Both the design and the dimensions are created together with you in accordance with the requirements. Production starts when the solution is finalized and agreed by you. However, the cooperation does not end with the completion of the product: we provide technical support over the entire lifetime of the product. This will give you long-term stable solutions that you can rely on.

In the development of measurement systems, we are always following a modular approach in order to offer our partners a great deal of flexibility. Thanks to the modular design principle, our solutions can also be easily integrated into existing systems. We are always available for inquiries: here, our priorities are speed, competence and simplicity. Our success is proven. With nearly three decades of experience, we have established ourselves as a leading provider of customized, modular pressure measurement sensors. Our customers value the expertise and the service orientation of our employees in the development of suitable solutions. Clearly, STS develops measuring technology from Engineers for Engineers.

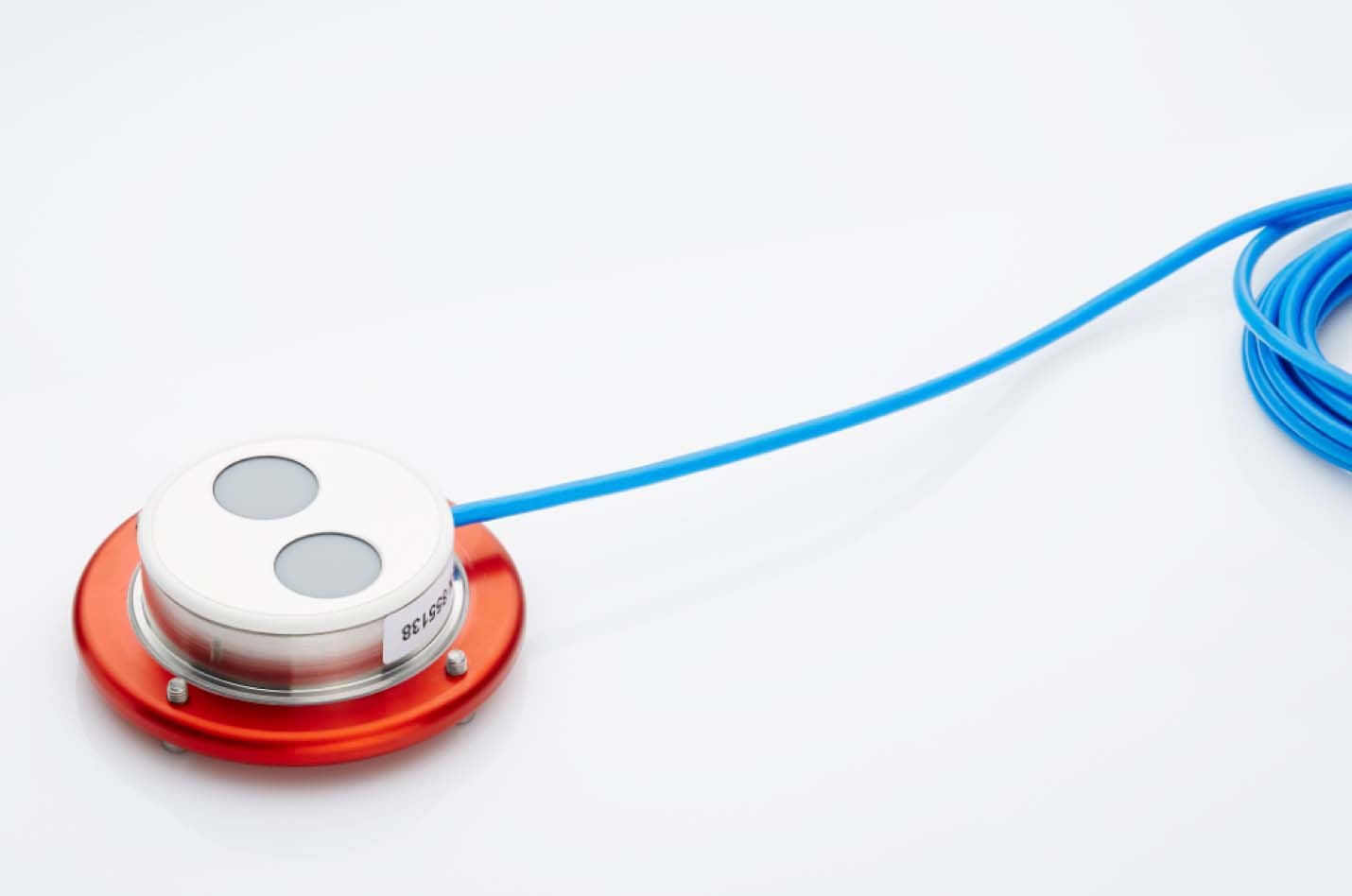

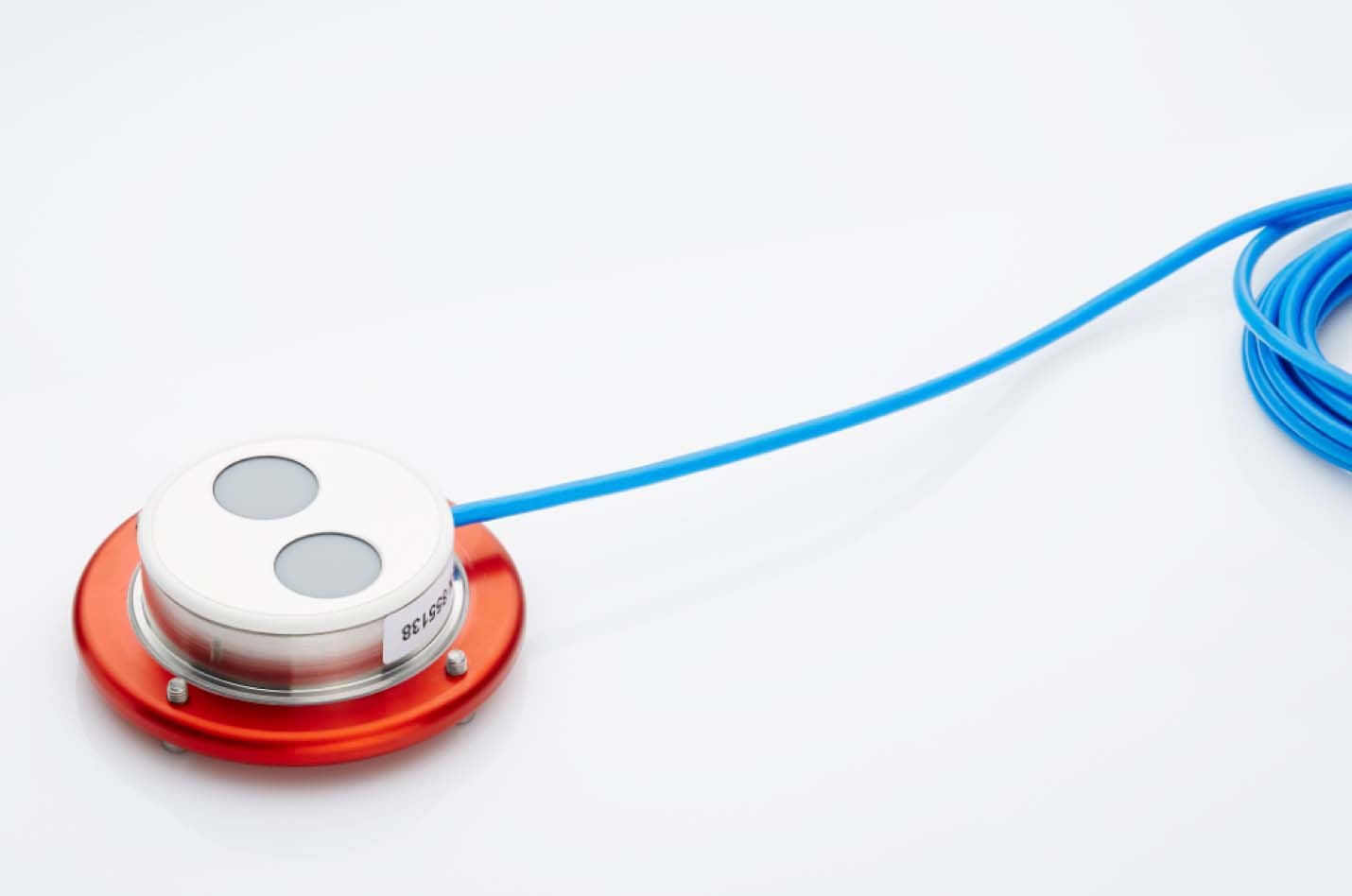

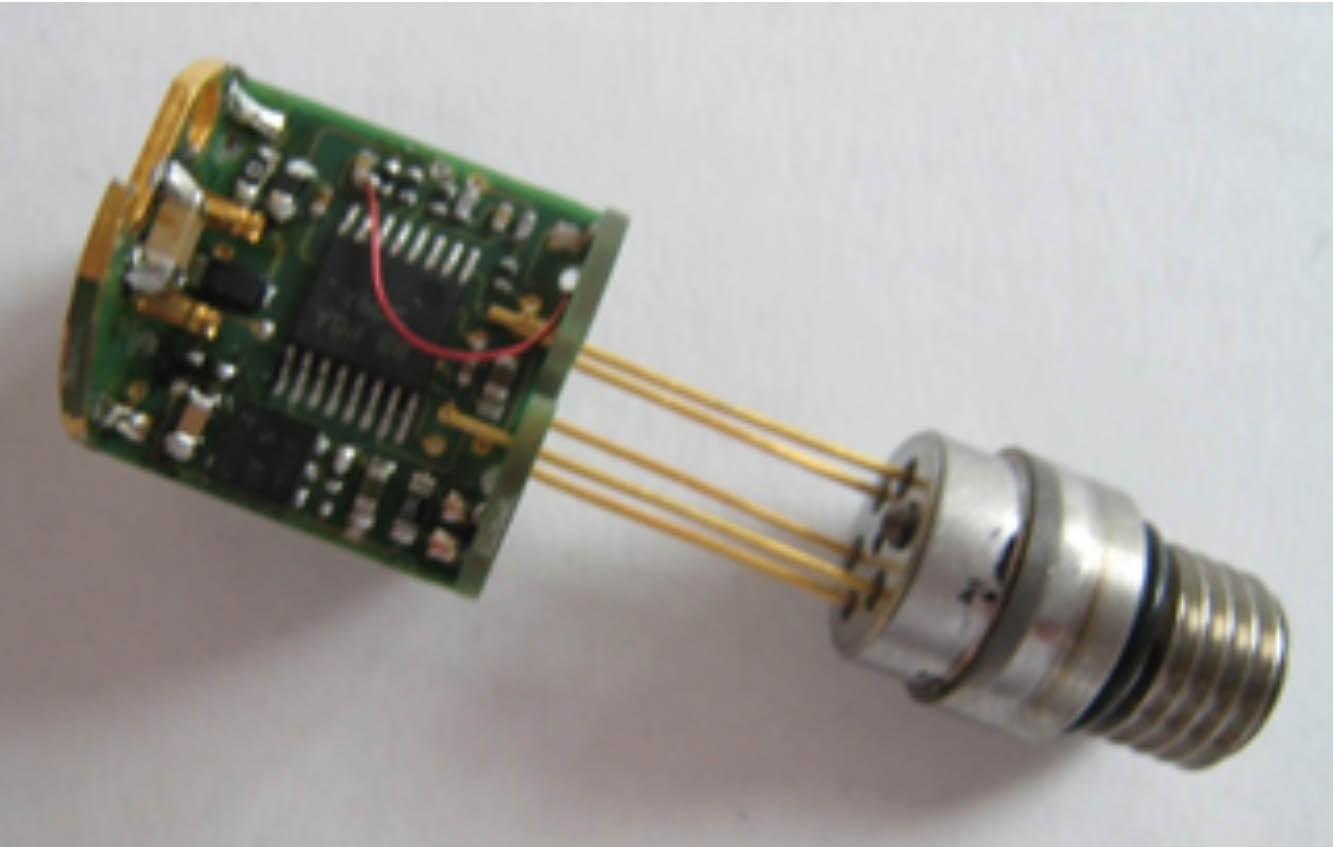

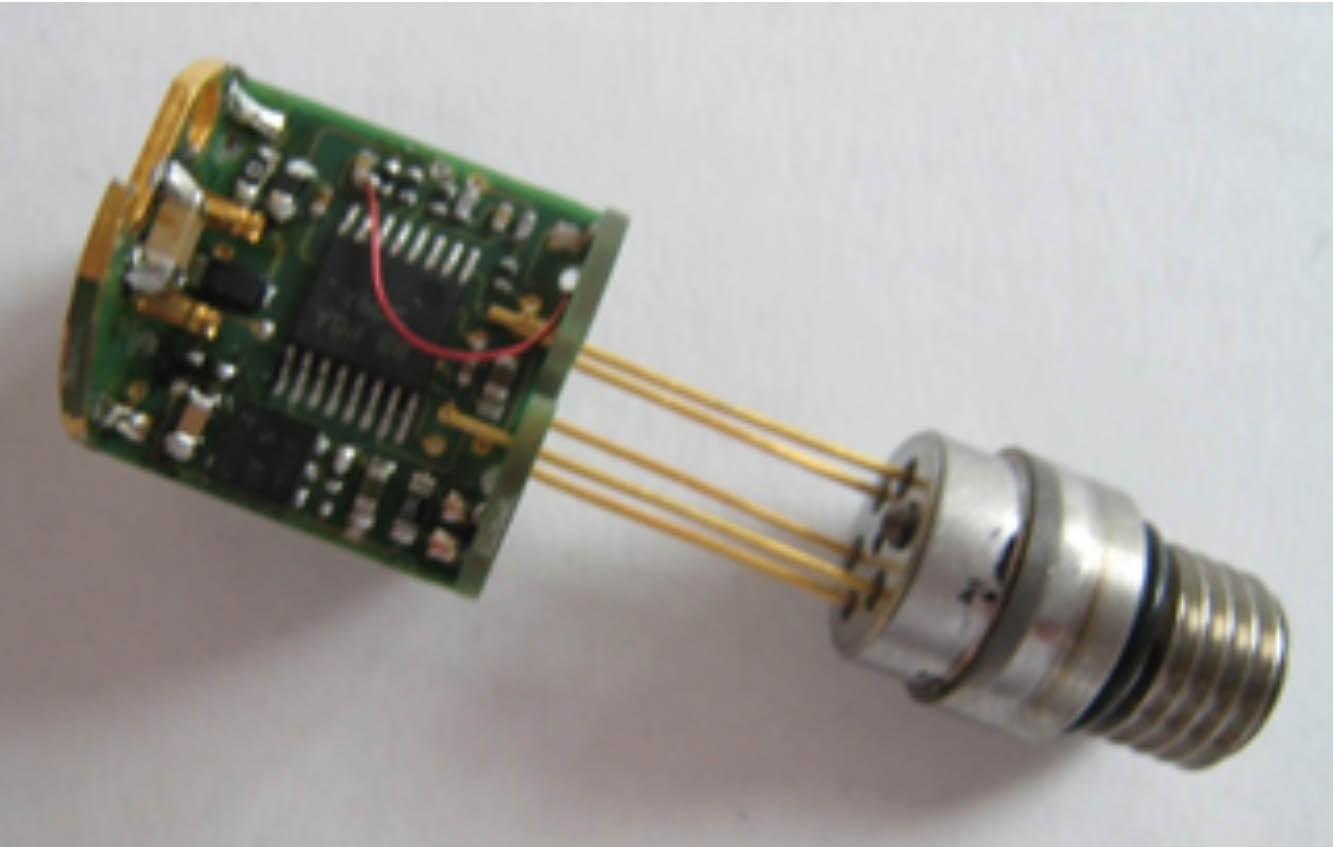

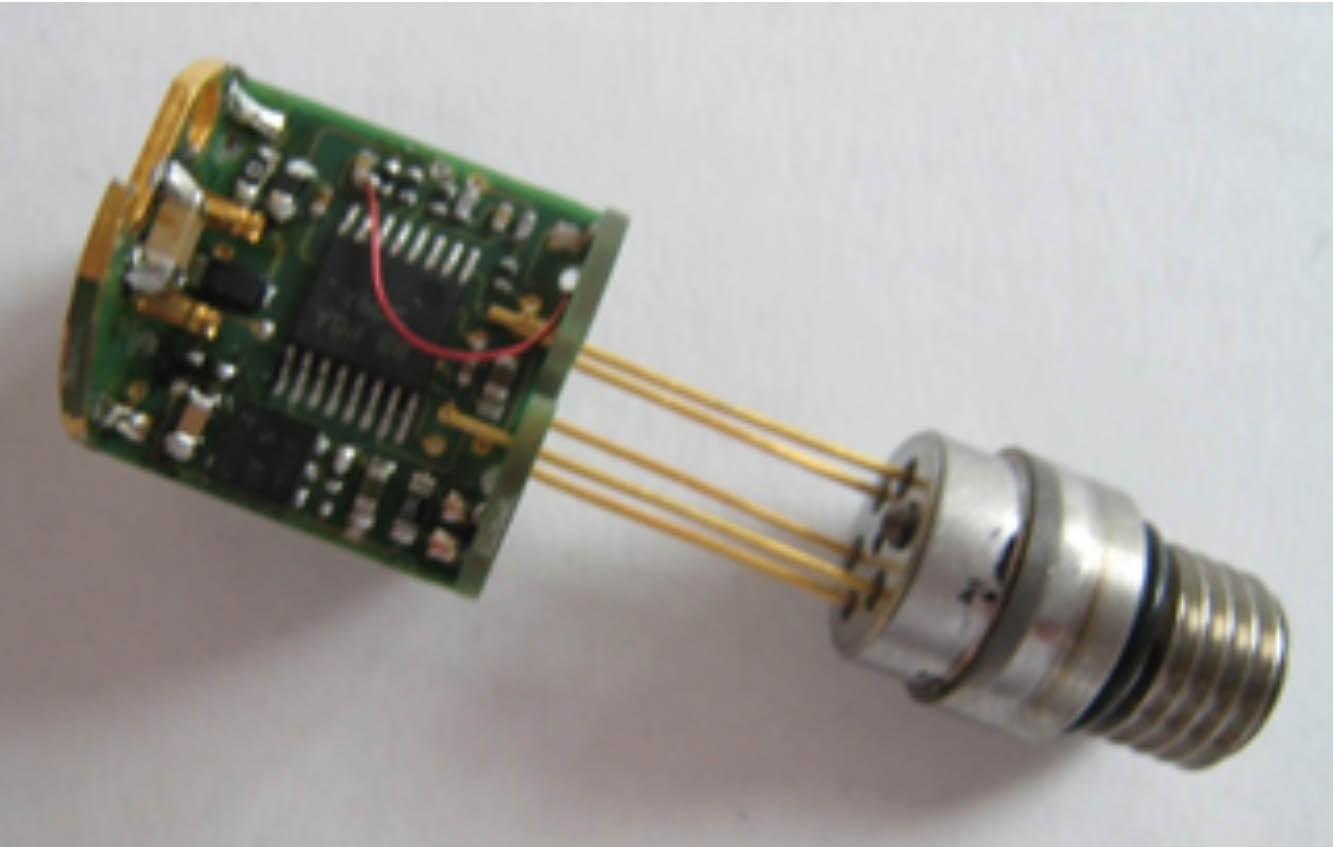

OEM transducer with integrated temperature compensation

Application example: depth measurement on CTD Probes

More about the application ➔ competence platform

Main features

- Salt water resistance

- High accuracy: temperature compensation and long term stability

- Low power consumption

- salt water resistance

Specifications

-

Pressure measurement range: 0-2b/0-5b/0-10b/0-50b/0-100bar absolute

-

Overload: 3x FS

-

Burst pressure: >850 bar

-

Accuracy: ≤±0.05 % FS.

-

Total error (-5ºC … 35ºC): ≤ ±0.1 % FS

-

Long-term stability: ≤ ±0.1 % FS/year.

-

Supply voltage: 5 V ± 0.25V

- Output signal: 0.5 – 4.5 V

-

Power consumption: < 11 mWatt

- Material: Hastelloy

Filling machine for injection bags

Application

Filling machine for injection bags

Specifications

-

ATM/F analog pressure/temperature transmitter with clamp flange 1 inch,

-

Connector Binder 723, 5 pins demountable

-

Accuracy +/- 0.1% FS

-

Oil filling: certified for food applications

Similar standard products

➔ ATM/F

Explosion Protection Device

Application

The sensor system is used to monitor static or dynamic pressure (explosion) on tank systems. A wide variety of media are measured, mostly organic or inorganic dusts, dyes, salts, solvents, alkalis and acids (cleaning) etc. The sensor is always mounted above the maximum level of the tank.

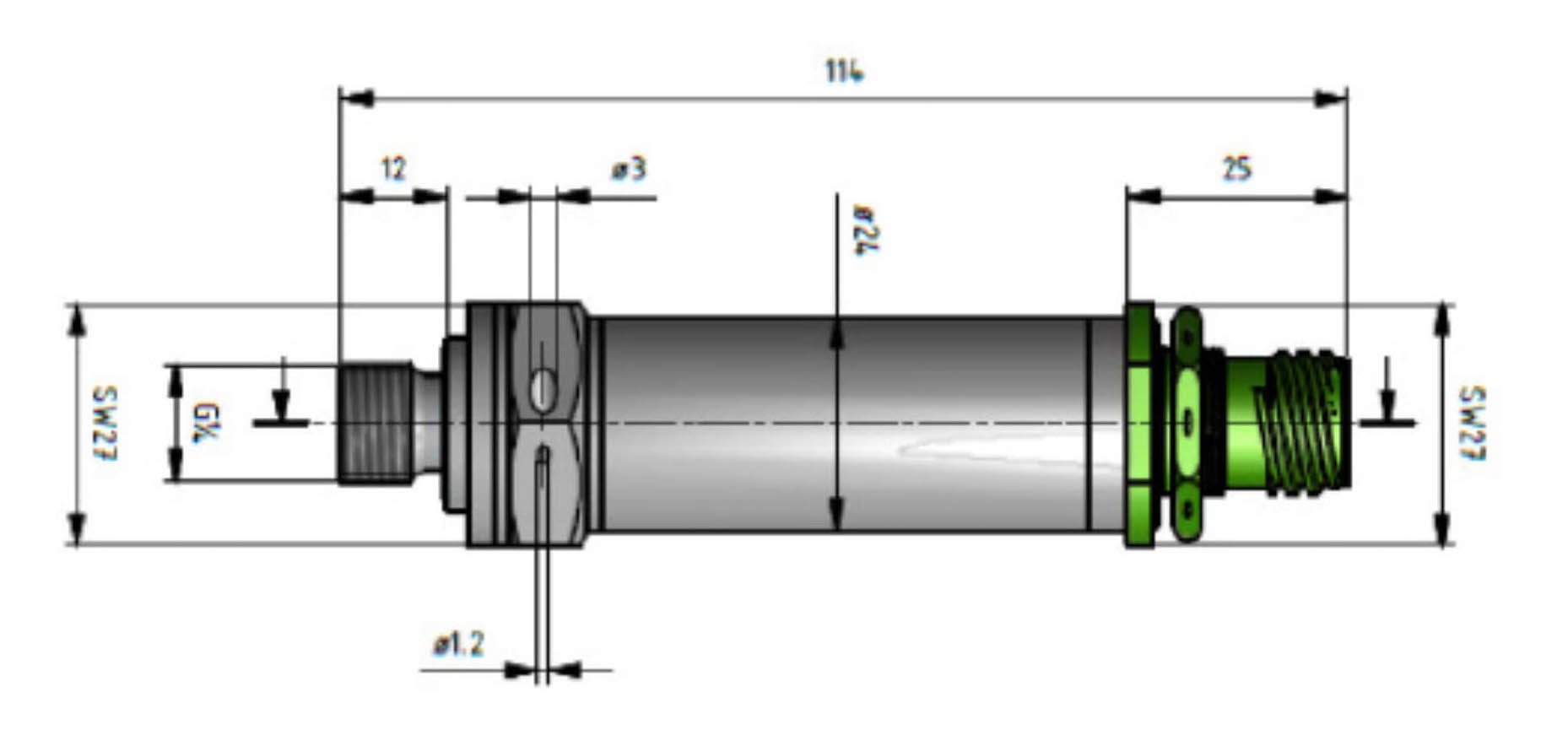

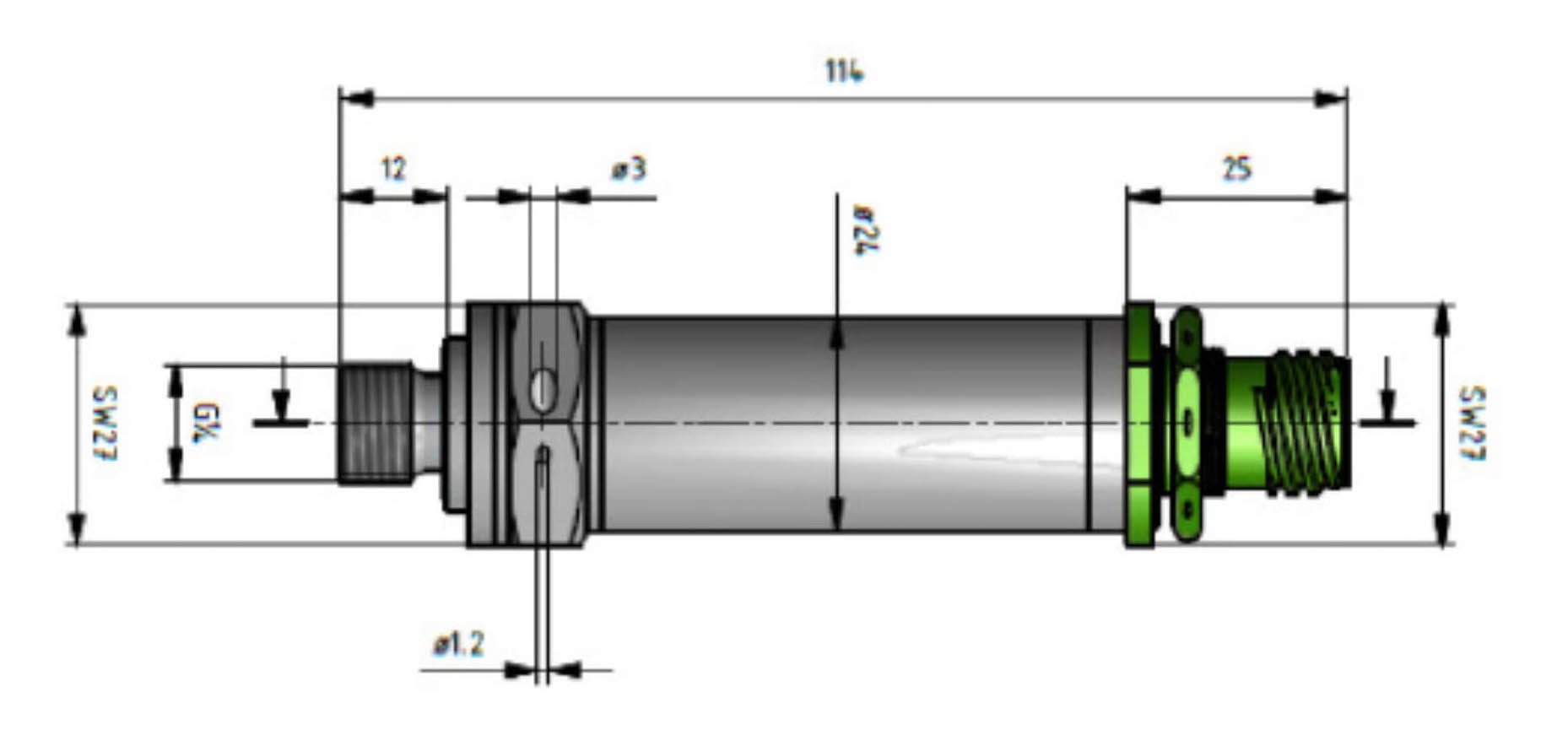

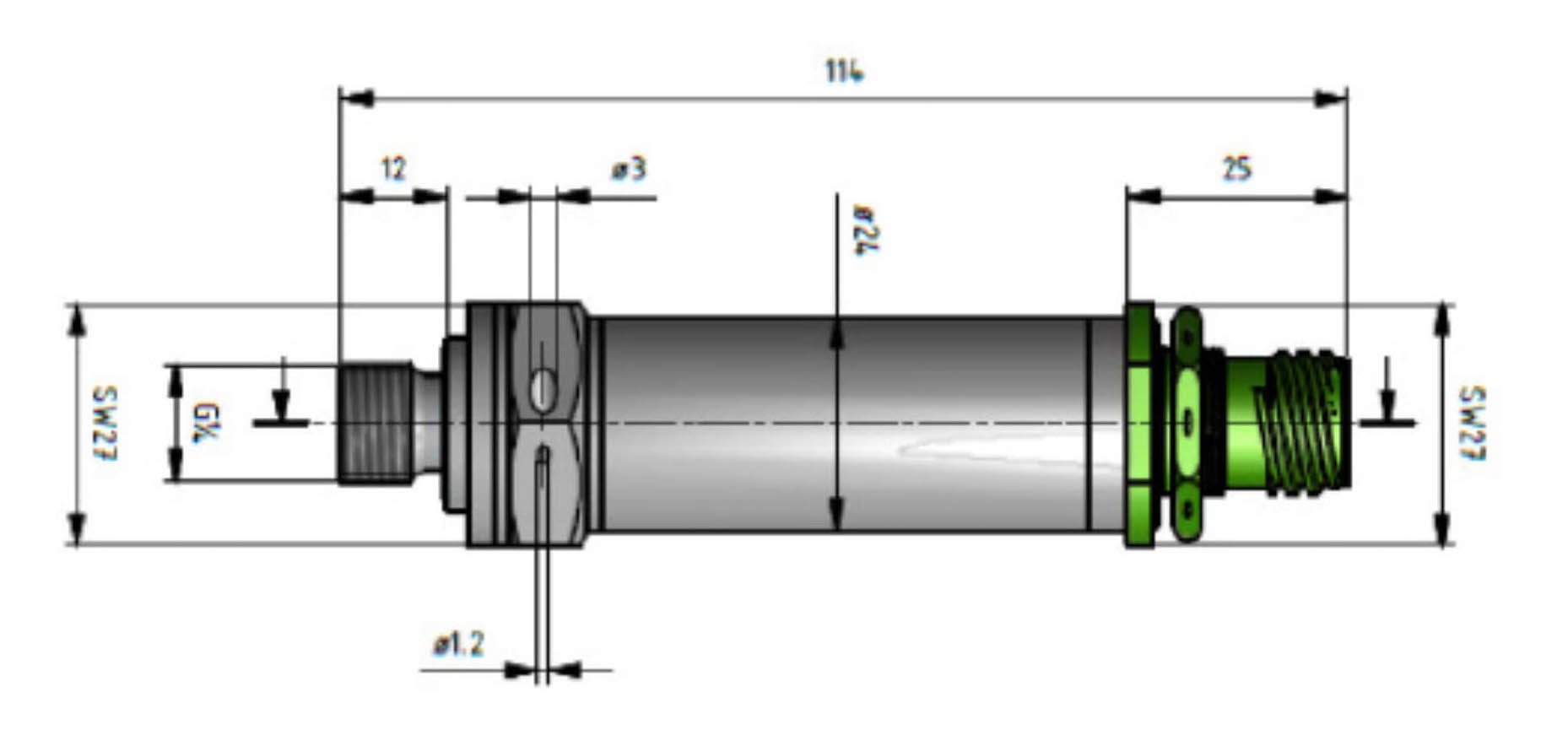

Controlling fuel pressure on a jet engine

ATM.1ST

- Pressure range 0 … 0.8 MPa, absolute

- Process connection G 1/4 M, with 2 boreholes Ø 1.2 mm in hex

- Electrical connection Connector MIL 38999, 10SL, 5/8″-23 A

- Maximum process temperature 125°C

- Accuracy <=+/- 0.1% FS

- Compensated temperature range: -40 … 125°C

- Version welded

- Electronic packed in gel

- Seal copper 9

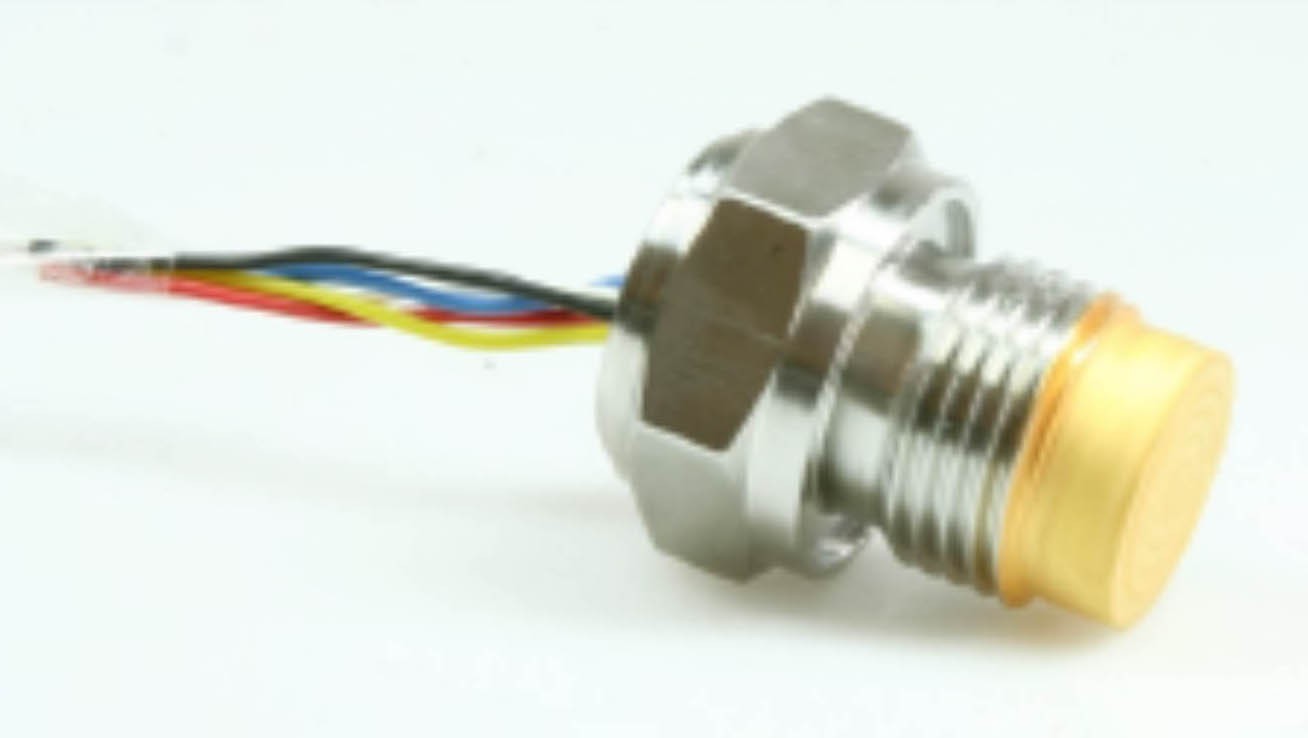

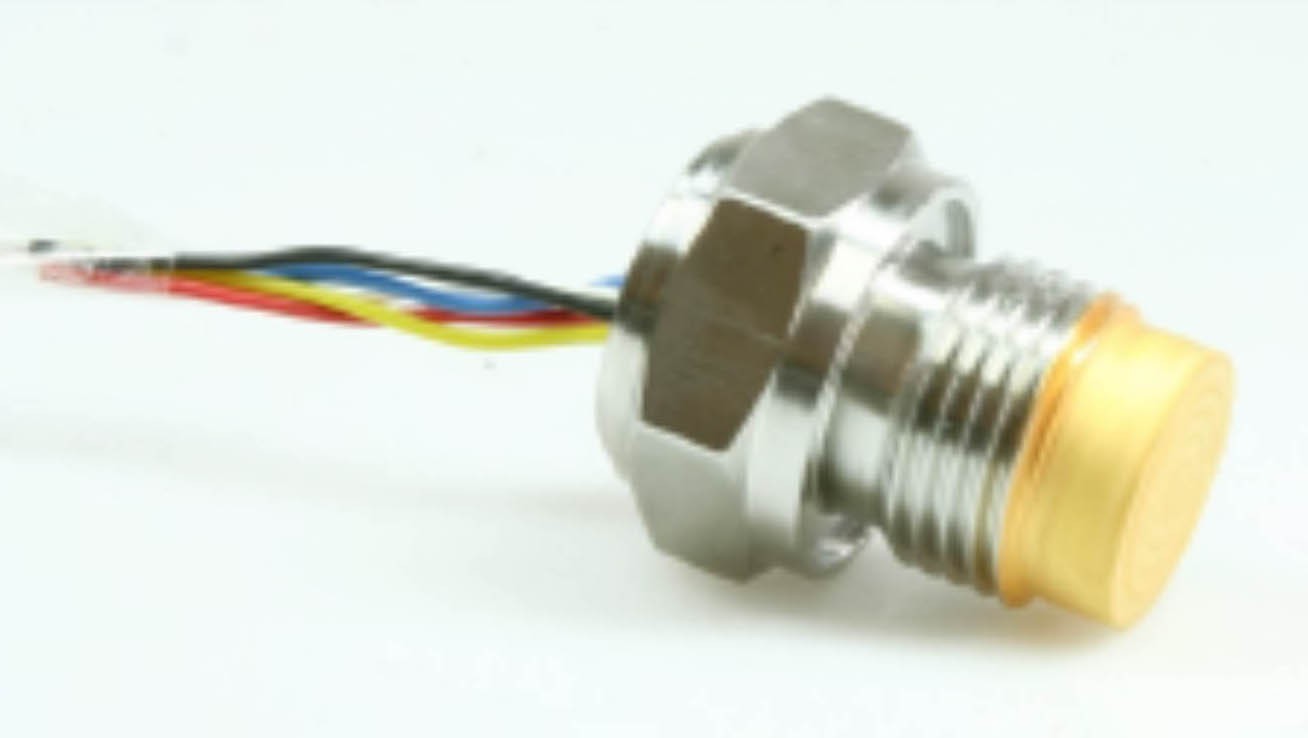

Hydrogen-powered fuel cells

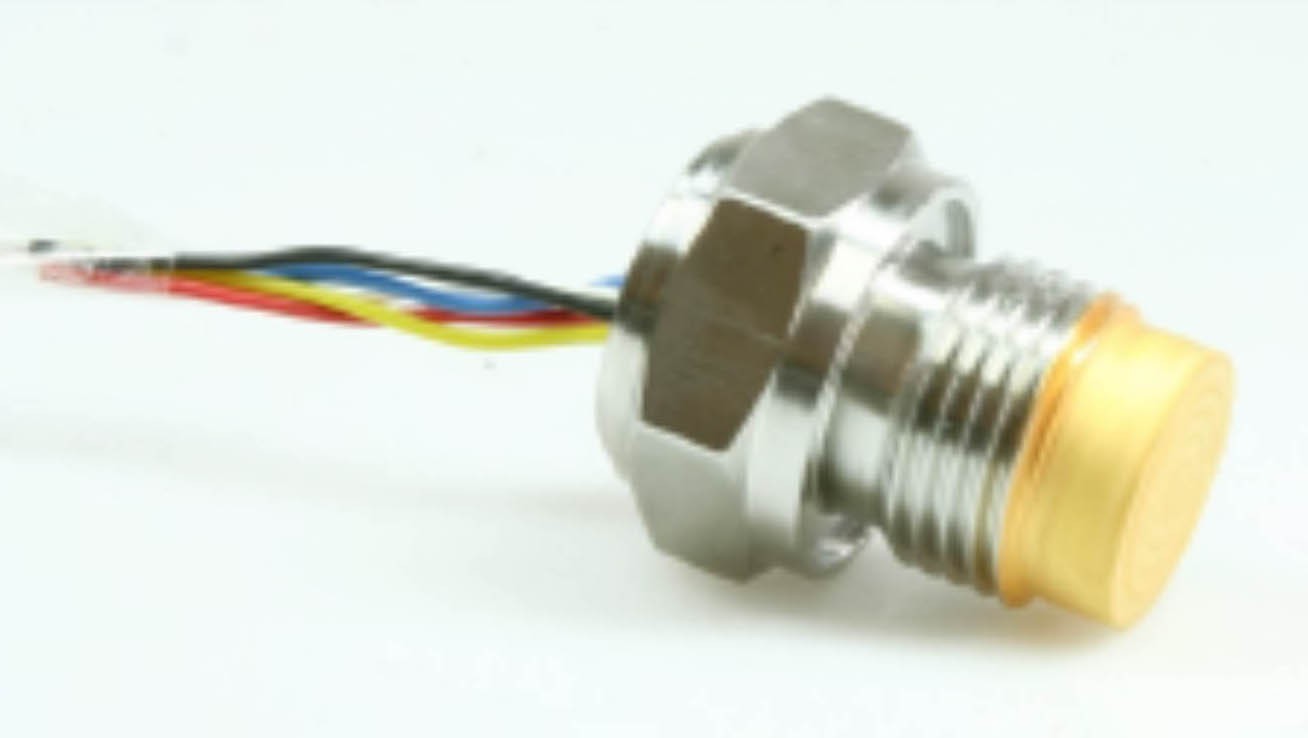

ATM/T Pressure and temperature sensor

- Pressure range 0 … 20 bar, absolute

- Overpressure 3xFS

- Process connection G 1/2 M, flush diaphragm, gilded

- Electrical connection Stecker Lumberg RSF 4, 4 polig

- Temperature measuring range -40 … 125°C

Similar blog

Hydrogen applications

Application

Gold platted transducer for hydrogen application

Only with pressure connection G 1/2″ male flush

Pressure ranges not below 1 bar and not over 600 bar

The gold coating is about 0.1 … 1 μm

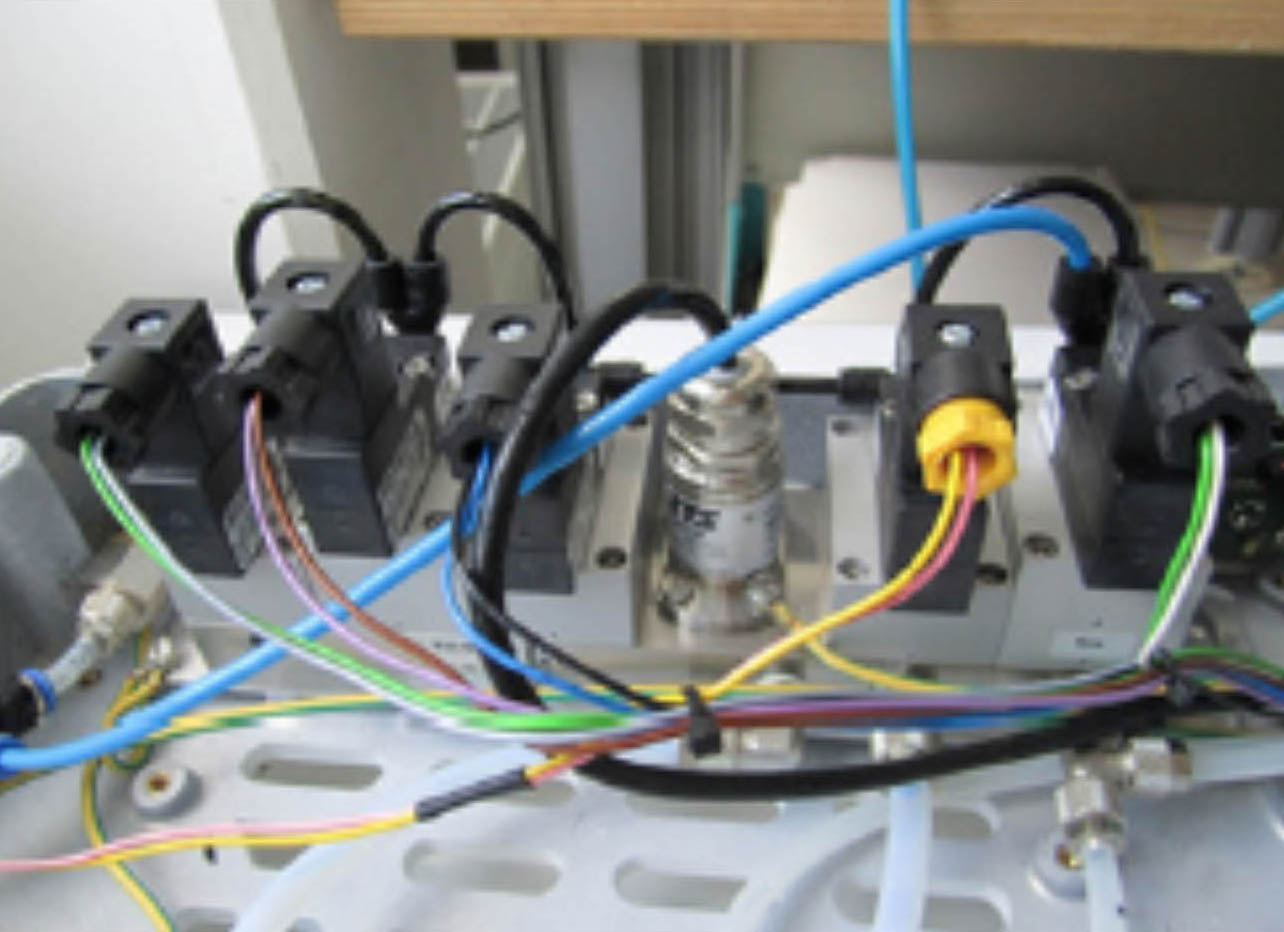

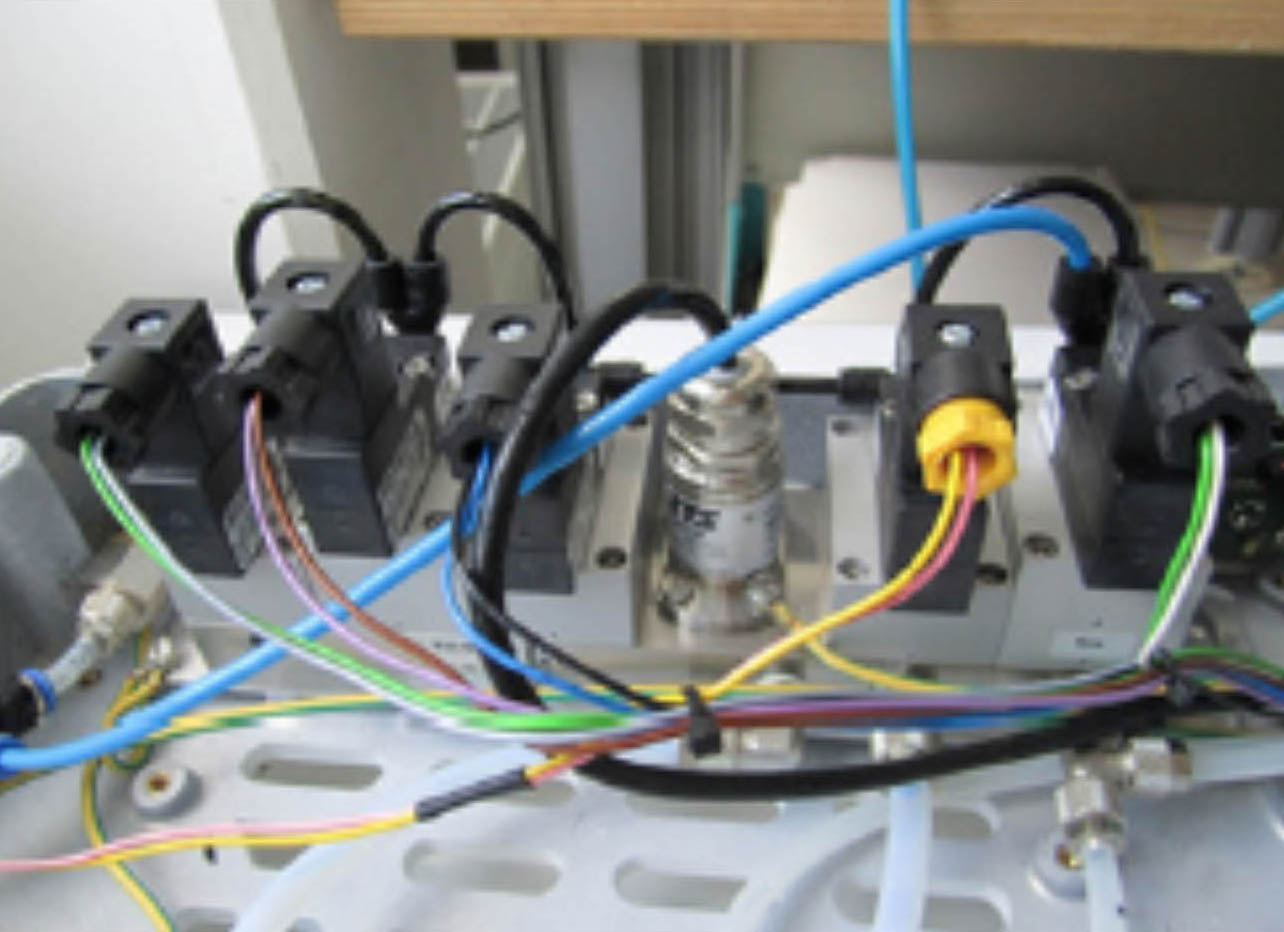

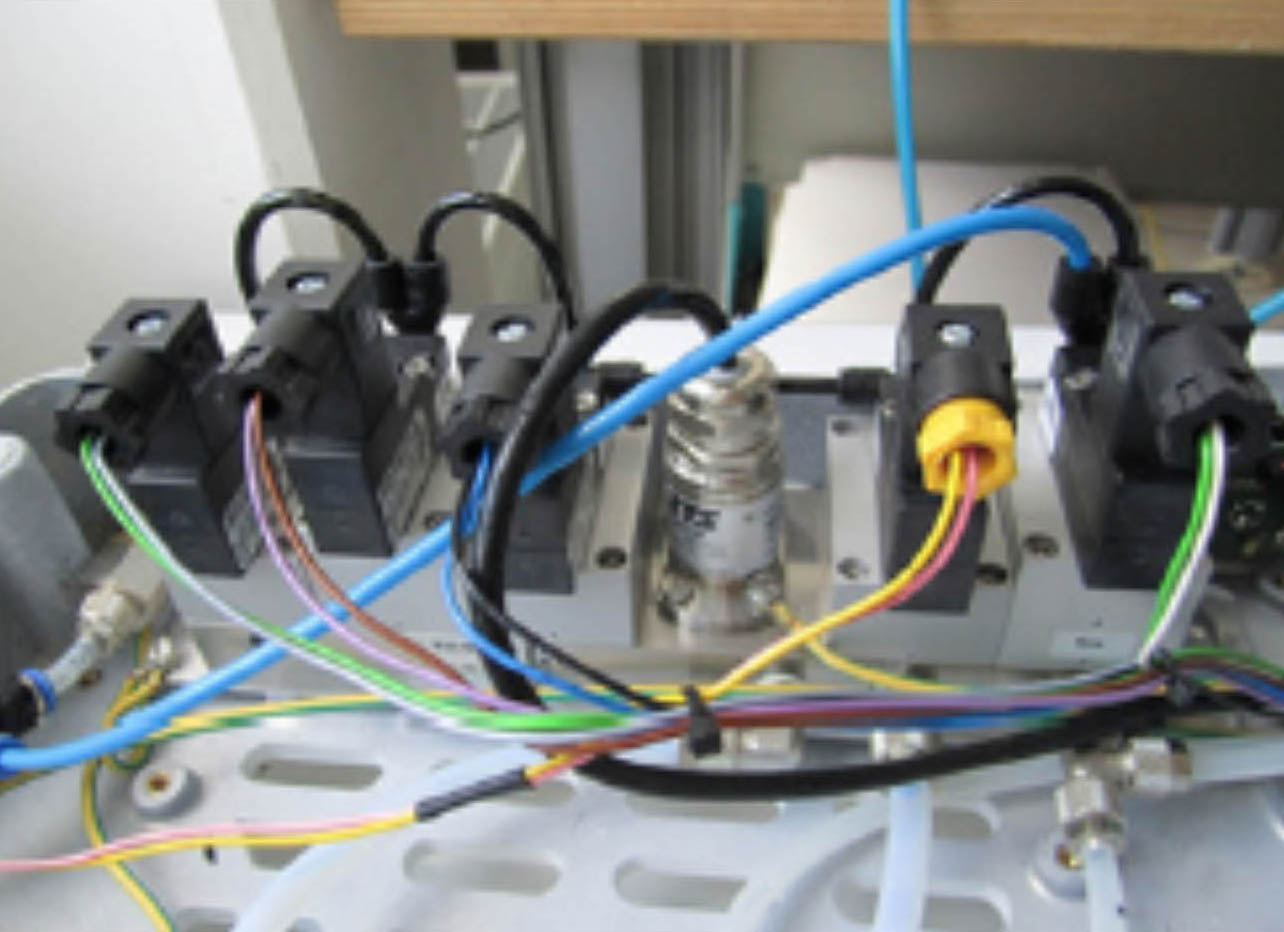

Filter integrity tester in medical application

ATM/F/Ex

- Pressure range 0.6 … 7.8 bar, absolute

- Process connection Flange Ø 18.4/9.5 mm (2.01.0271)

- Electrical connection PUR cable, connector Samtec IPD1-05-D-K

- Output signal 4 … 20 mA

- Power supply 10 … 30 V DC

- Maximum process temperature 100°C

- Accuracy <=+/- 0.1% FS

- EEPROM integrated in the sensor

Barometric pressure for environmental analyses

TM passive transmitter

- Pressure range 850 … 1150 mbar, absolute

- Process connection G 1/4 A, with nozzle

- Electrical connection PUR wires 500mm, 4 x 0.2 mm2

- Maximum process temperature 150°C

- Special feature: Calibrated horizontally

Helium pycnometer “Measuring Fine Powders”

Application

Helium pycnometer is a measuring device for determining the density of solids or liquids by weighing.

Transducer with Flange

- Pressure range 0 … 2.5 bar, absolute

- Overpressure 7.5 bar

- Version Flange welded Ø 24/19×36 mm (2.01.0403)

- Accuracy <± 0.25 % FS

- Temperature range +10 … +40°C

- Thermal shift zero point ± 0.15 % FS

- Thermal shift span ± 0.3 %

Leak testing of venous catheter

Type ATM.1ST

- With improved dead volume

- Pressure range 0 … 0.8 bar gauge

- Process connection G1/2 male, flush, no HEX, Ø 24 mm

- Electrical connection Lumberg RSF 4, 4-pole

- Accuracy <=+/- 0.05% FS

- Temperature compensation: 0 … 70°C

Polyurethane injection to strengthen or repair the tunnel wall construction

ATM.1ST

- Pressure range 0 … 100 bar, sealed gauge

- Overpressure 3xFS

- Membrane 100 micro

- Process connection M22 x 1.5 M, flush diaphragm

- Electrical connection connector DIN 43650, metal thread

- Accuracy <=+/- 0.1% FS

- Seal Viton

Biogas production

ATM/N

- Pressure range 0.5 … 2.5 bar, absolute

- Process connection G 1/4 male

- Electrical connection PUR Kabel

- Compensated temperature range: -5 … 50°C

- Seal Viton

Subsea Control Units – Water ingress detector

Subsea application

The water ingress detector is used to measure a possible leak of saltwater ingress into the Subsea Control Unit

Water ingress detector

- Alarm levels 3 different alarm levels

- Accuracy ± 0.3 mA

- Electrical connection 6 pin glass-to-metal seal

- Temperature range -20 to 85°C

Subsea BOP control system

ATM Subsea with special Seacon, type MSSK connector

- Pressure ranges 0 to 1‘000 bar

- Process connection 7/16-20 UNF female

- Electrical connection Seacon, Typ MSSK-8#16-FCR-HP

- Temperature range -10 to 50°C compensated

Hydraulic pressure measurement in Subsea Control Module with water ambient pressure of 370 b

ATM Subsea with special Seacon connector

- Pressure ranges: 0 to 15‘000 psi (0 … 1034 bar)

- Process connection: ¼ NPT female, including pressure snubbers

- Electrical connection Seacon, type 5507-2003-0004, 3 pins

- Temperature range -10 to 50°C compensated

Subsea Control Modules Pressure monitoring at the solenoid of the Subsea Control Unit

ATM Subsea, right angled connection

- Pressure ranges 0 to 690 bar / 1034 bar / 1380 bar

- Process connection Flange with double o-ring seal

- Electrical connection 2 pin glass-to-metal seal

- Temperature range -10 to 40°C compensated

Subsea Control Modules

ATM with bulkhead fitting

- Pressure ranges 0 to 350 bar / 850 bar

- Process connection 5/16 – 24 UNF, including pressure snubber

- Electrical connection Binder connector 723, 5-pins

- Temperature range -25 to 150°C

Measurement of hydrate deposits in 4000m water depth

Type Transducer

- Housing material Titanium

- Pressure range 0 … 450 bar, sealed gauge

- Overpressure 500 bar

- Process connection Ø 15 mm x 4.9 mm, flush diaphragm

- Electrical connection 5 gold plated pins

- Compensated temperature range 0 … 70°C

- Seal: Viton

Filter monitoring in helicopters

ATM/GR

- Pressure range 0 … 50 mbar, gauge

- Pressure connection 1/4 NPT A

- Electrical connection Hytrel wires, green, marked

- Wires soldered to the glass-to-metal seal

- Differential press. conn. G 1/4 female

- Switch point 1 20.5 +/- 0.5 mbar

- Switch point 2 25.5 +/- 0.5 mbar

- Compensated temperature range: -25 … 85°C

- Oil filling AS 100 for medium temperatures of -55 … 150°C

Refrigerant test rigs for automotive and aviation test benches

ATM.Mini

- Pressure range 0 … 50 bar, absolute

- Process connection 7/16-20 UNF A, SW19

- Version Welded

- Electrical connection Connector Lumberg RSF 4, 4-pin

- Max medium temperature 100°C

- Compensated temperature range: -25 … 100°C

- Available pressure connections:

M8 x 1 A, SW19

3/8-24 UNJF-3A, SW19

Hydraulic weighing system

TM

- Pressure range 0 … 400 bar, sealed gauge

- Overpressure 850 bar

- Process connection G 1/2 A

- Electrical connection Connector DIN 43650, metal thread

- Maximum process temperature 150°C

Chemical tank

Field housing and DIN flange

Available for:

ATM, ATM/Ex, ATM.1ST, ATM.1ST/EX, PTM, PTM/Ex

- Compact and robust stainless steel version in 316 L

- Electrical connection, brass connection

- Spring terminals 1,5 mm² , PG 15

- Spring terminals and zero point potentiometer inside the field housing, so an easy installation is guaranteed.

- Measuring ranges according to DIN series between -1 bar to 25 bar, special calibrations possible

- High reliability, reverse polarity and short-circuit proof.

Hydraulics

ATM.ECO with special connector

- Pressure range 0 … 210 bar sealed gauge

- Process connection G 1/4 A

- Electrical connection Hirschmann G4A1M

- Max medium temperature 125°C

- Compensated temperature range 0 … 70°C

- Viton seals

Blowing pressure in tire production

ATM

- Pressure range -1 … 32 bar, gauge

- Overpressure 3xFS

- Process connection G 1/2 male, manometer DIN 16288

- Electrical connection connector DIN 43650, metal thread

- Accuracy <=+/- 0.1% FS

- Compensated temperature range: -25 … 85°C Seal Viton

Battery testing

Transducer with print

- Pressure range 0… 5 bar

- Process connection: M8 x 1A, SW11 welded

- Seal : NBR

High-vaccum technology

Typ ATM absolute

- Pressure range 0 … 350 mbar

- Process connection: Tub stub Ø 24/6.4 mm

- Electrical connection: RJ45

Cable: connector side 1200 mm

Cooling filling systems Automotive industry

Type ATM/X

- Sensor 1

- Pressure range 0 … 100 mbar, absolute

- Accuracy <± 0.25 % FS

- Sensor 2 : for brake fluid

Production of water glass

TM, Passive Transmi5er with cooling element

- Process temperature: up to 250 C 0 …30 bar, gauge

- Process connec$on G 1/2 A,

- Manometer DIN 16288

- Electrical connec$on PTFE cable

- Compensated temperature range: -25 … 85°C

- Seal Viton

Testing of gear boxes

TM, Passive Transmitter, side vented

- Pressure range 0 … 10 bar, gauge

- Process connection M14 x 1.5 A, HEX24 welded

- Electrical connection MIL C26482, 10-6

- Medium temperature 150°C

- Temperature range -25 … 100°C compensated

- Electronic packed in gel