Electronic pressure measurement: Comparison of common measuring principles

Electronic pressure transmitters are used in a variety of applications, from machine technology to the manufacturing sector right through to the foodstuffs and pharmaceuticals industries. The recording of the physical size of pressure can take place via different measuring principles. We introduce the common technologies here.

In electronic pressure measurement, a distinction is usually made between thin-film sensors, thick-film sensors and piezoresistive pressure sensors. It is common to all three measurement principles that the physical quantity of pressure is converted into a measurable electrical signal. Equally fundamental to all three principles is a Wheatstone bridge: a measurement device for the detection of electrical resistances, which itself consists of four interconnected resistors.

Piezoresistive pressure sensors: High-precision and cost-effective

Piezoresistive pressure sensors are based on semiconductor strain gauges made of silicon. Four resistors connected to a Wheatstone bridge are diffused onto a silicon chip. Under pressure, this silicon chip will deform and this deformation then alters the conductivity of the diffused resistors. The pressure can then ultimately be read from this shift in resistance.

Because the piezoresistive sensor element is very sensitive, it must be shielded from the influence of the measuring medium. The sensor is therefore located inside a diaphragm seal, with pressure being transmitted via a liquid surrounding the sensor element. The usual choice here is silicone oil. In hygienic applications such as in the foodstuffs or pharmaceuticals industries, however, other transfer fluids are also used. A dry measuring cell from which no liquid will escape in the event of damage is not possible.

The advantages:

- very high sensitivity, pressures in the mbar range measurable

- high measuring range possible, from mbar to 2,000 bar

- very high overload safety

- excellent accuracy of up to 0.05 percent of span

- small sensor design

- very good hysteresis behavior and good repeatability

- basic technology comparatively inexpensive

- static and dynamic pressures

The disadvantages:

- transfer medium required

- temperature compensation necessary

Thin-film sensors: Long-term stability but expensive

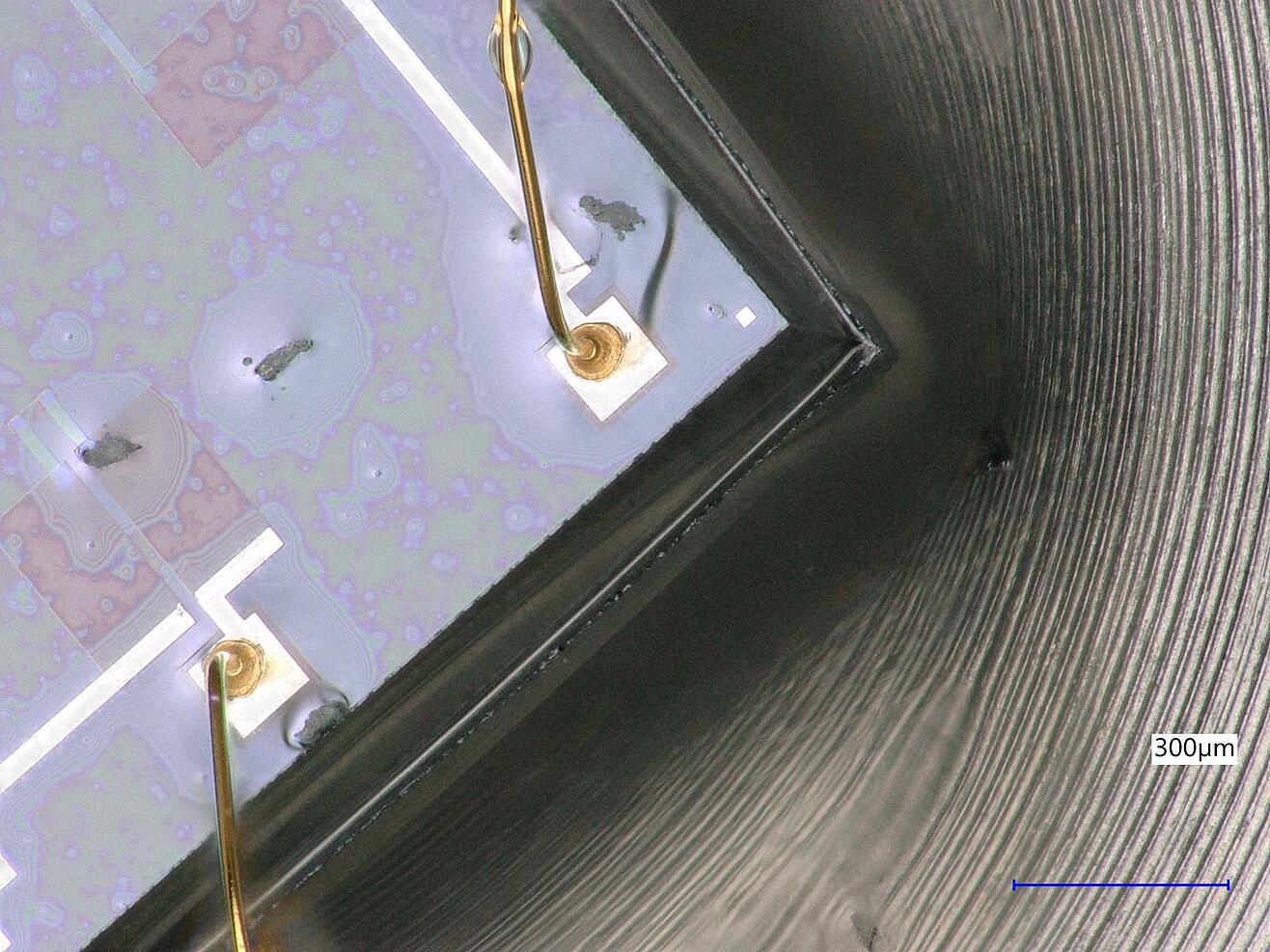

In contrast to piezoresistive pressure sensors, thin-film sensors are based on a metallic main body. Upon this, the four resistors connected to a Wheatstone bridge are deposited by a so-called sputtering process. The pressure is thus detected here also by a change in resistance caused by deformation. Besides the strain gauges, temperature compensation resistors can also be inserted. A transfer liquid, as in the case of piezoresistive pressure sensors, is not necessary.

The advantages:

- very small size

- pressures up to 8,000 bar measurable

- outstanding long-term stability

- no temperature compensation required

- high accuracy

- high burst pressure

- static and dynamic pressures

The disadvantages:

- lower sensitivity than piezoresistive sensors, so low pressures are less measurable

- basic technology comparatively expensive

Thick-film sensors: Particularly corrosion-resistant

Ceramics (alumina ceramics) serve as the basic material for thick-film sensors. These pressure sensors are monolithic, meaning that the sensor body consists of only one material, which ensures an excellent long-term stability. Furthermore, ceramics are particularly corrosion-resistant against aggressive media. With this type of sensor, the Wheatstone bridge is printed onto the main body by means of thick-film technology and then baked on at high temperature.

The advantages:

- very good corrosion resistance

- no temperature compensation required

- good long-term stability

- no diaphragm seal needed

The disadvantages:

- not suitable for measuring dynamic pressures

- limited upper pressure range (about 400 bar)