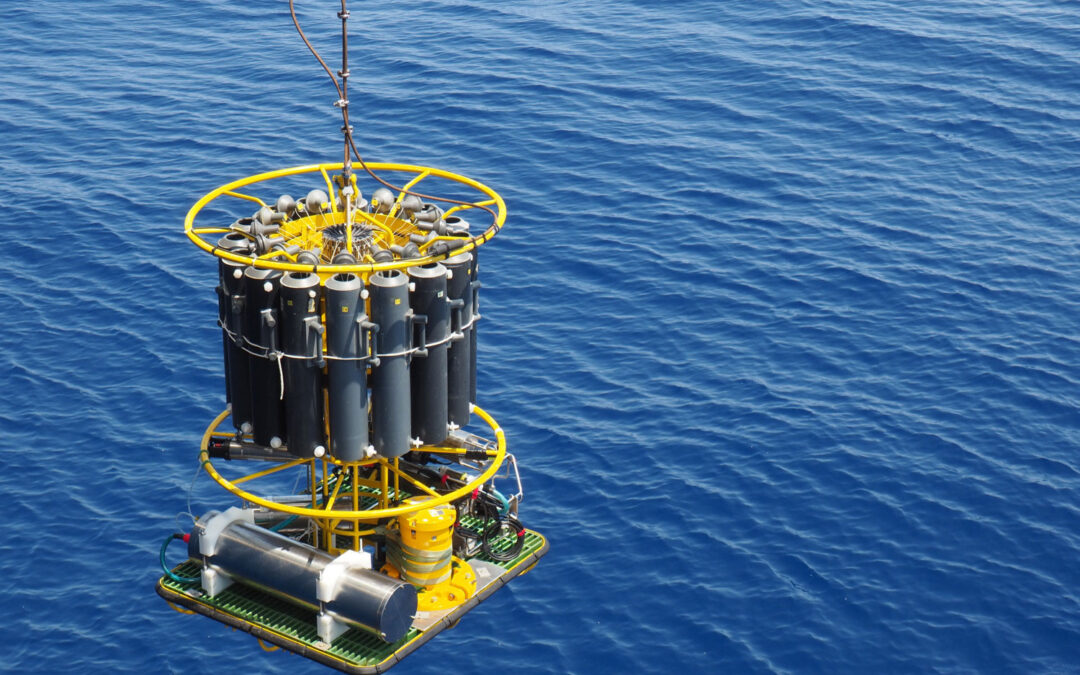

CTD (Conductivity, Temperature, Depth)

A CTD – an acronym for conductivity, temperature, and depth – is the primary instrument used to determine the essential physical properties of seawater. It provides scientists with an accurate and comprehensive representation of the distribution and variation of water temperature, salinity, and density to understand how the oceans affect life.

How it works.

The CTD on board consists of a set of small probes attached to a large metal rosette wheel. The rosette is sunk to the seafloor via a cable, and scientists monitor water properties in real time via a data cable that connects the CTD to a computer on the ship. A remote-controlled device allows the water bottles to be selectively closed during the ascent of the instrument. A standard CTD takes between two and five hours to collect a complete data set, depending on water depth. Water samples are often collected at specific depths so scientists can learn about the physical properties of the water column at that particular location and time.

Small, low-power CTD sensors are also used in autonomous instruments:

A moored profiler makes repeated measurements of ocean currents and water properties up and down through almost the entire water column, even in very deep water. The basic instruments it carries are a CTD for temperature and salinity and an ACM (acoustic current meter) to measure currents, but other instruments can be added, including bio-optical and chemical sensors.

Spray Gliders roam the ocean independently, running pre-programmed routes and surfacing occasionally to transmit collected data and accept new commands. As they cruise horizontally through the ocean, internal bladders control their buoyancy, enabling them to navigate up and down through the water column like whales and other marine animals.

Floats are floating robots that take profiles or vertical series of measurements (e.g., temperature and salinity) in the oceans.

Autonomous Underwater Vehicles (AUV’s) are programmable, robotic vehicles that, depending on their design, can drift, drive, or glide through the ocean without real-time control by human operators. Some AUVs communicate with operators periodically or continuously through satellite signals or underwater acoustic beacons to permit some level of control.

What platforms are needed?

A variety of other accessories and instruments may be included with the CTD package. These include Niskin bottles that collect water samples at various depths to measure chemical properties, acoustic Doppler current profilers (ADCP) that measure horizontal velocity, and oxygen sensors that measure dissolved oxygen levels in the water.

Features of the CTD’s sensors

- Saltwater resistant

- High accuracy

- Lightweight

- Low power consumption

- Will be used at depths up to several thousand meters

Comments:

The small low power CTD sensors used on autonomous instruments such as water column profilers, spray gliders, floats and AUV’s are more complex to operate. The main limitation is the need to calibrate the individual sensors. This is especially true for autonomous instruments that are deployed for extended periods of time. (Ship CTDs are referenced to water sample data, which is generally not available for autonomous instrument deployments). Therefore, sensors must be stable for the deployment period, or assumptions must be made about seawater properties and referenced to the data. Deep water properties are typically very stable, so autonomous sensor data are matched to historical water properties at depth.

STS provides high precision pressure cells for this specific application.